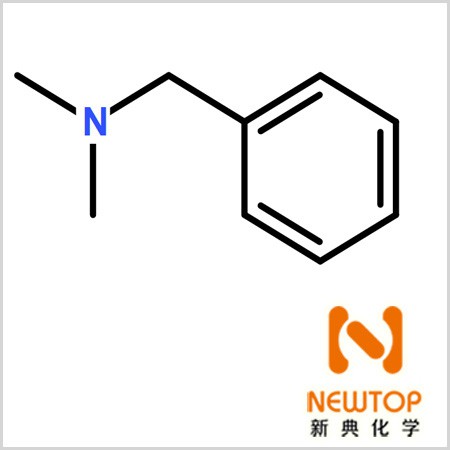

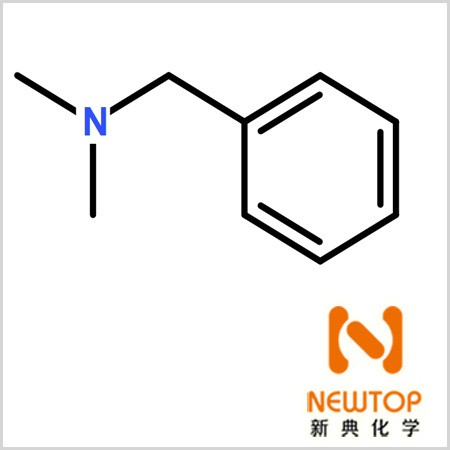

Dimethylbenzylamine CAS 103-83-3 N-dimthylbenzylamine

PU Catalyst: BDMA (benzyldimethylamine) CAS:103-83-3

Over view:

Common Name: Benzyl Dimethyl Amine

Other Chemical Names: N,N-Dimethylbenzylamine, Benzenemethamine, N,N-dimethyl-;Benzenemethanamine,N,N-dimethyl-;Benzylamine,

Physical and chemical properties:

| Appearance | Form: transprant light yellow liquid |

| Odour | no data available |

| PH | 10 at 10 g/l at 20 °C |

| Melting point/freezing point | Melting point/range: -75 °C – lit. |

| Initial boiling point and boiling range | 181 – 184 °C at 1.020 hPa – lit. |

| Flash point | 53 °C – closed cup |

| Evaporation rate | no data available |

| Flammability (solid, gas) | Upper explosion limit: 6,3 %(V) |

| Upper/lower flammability

or explosive limits |

Lower explosion limit: 0,9 %(V) |

| Relative density | 0,9 g/cm3 at 25 °C |

| Water solubility | soluble |

| Partition coefficient: noctanol/water | log Pow: 1,87 |

| Molar formular | C9H13N |

| Molar mass | 135.21 |

Features and uses:

A liquid tertiary amine catalyst. Can improve foam cure and demolding time. It is an excellent candidate to consider for use in water-NCO reaction in rigid polyurethane foams.

BDMA is typically suitable to replace DMCHA in formulations using a high level of water as blowing or co-blowing agent can reduce surface friability and improve adhesion of foam to substrates.

BDMA promotes the urethane reaction and is commonly used in high-water rigid foam applications to reduce friability. It has a characteristic but low amine odor, and is soluble in water and in most organic solvents.

BDMA is used in flexible slabstock and rigid foam applications.

It promotes the urethane reaction and is commonly used in high-water rigid foam applications to reduce friability.

BDMA is also used for flexible slabstock foam applications.

Storage Information

Recommends that our catalysts be stored in a dry and cool area under appropriate ventilation conditions. Each container should be closed tightly to avoid contamination with moisture or other negative influences that could change the products’ performance in the end use.

Package:

180KG/Steel Drum

(DABCO BDMA/Niax BDMA/ PC Cat NP60/ Addocat DB/ Jeffcat BDMA/ Lupragen N103)