Latest News: Recently, Liaocheng High-tech Industrial Development Zone issued an announcement that the environmental impact assessment document of Luxi Chemical’s 240,000 tons/year ethylene downstream integration project has been approved.

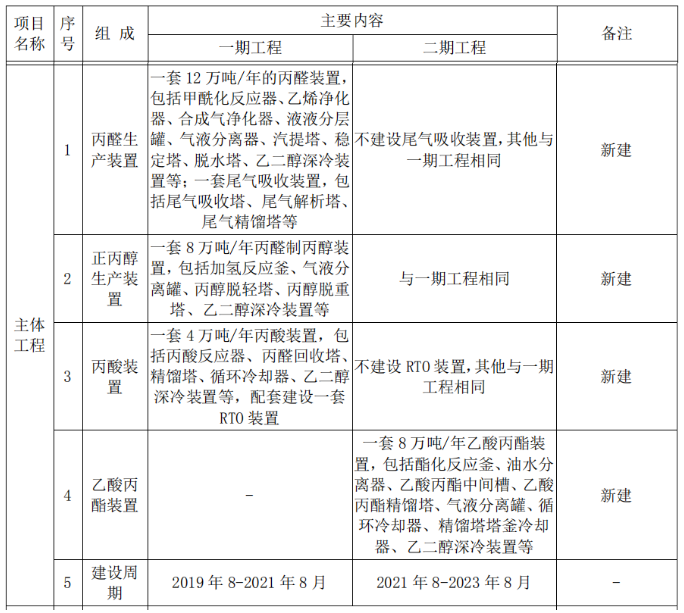

From the EIA documents, the main construction contents of the project are as follows.

Project name: 240,000 tons/year ethylene downstream integration project;

Nature of construction: New;

Constructor: Luxi Chemical Group Co., Ltd.;

Project investment: 1,186,219,900 yuan, including 355,866,000 yuan for the first phase and 830,353,900 yuan for the second phase;

Construction location: In Liaocheng Chemical Industrial Park, Liaocheng Economic Development Zone, with a total area of 62,000 square meters, of which the first phase of the project covers an area of 21,000 square meters

square meters, the second phase of the project covers an area of 41,000 square meters;

Construction period: 48 months, 24 months for the first phase, construction started in August 2019, construction completed in August 2021, 24 months for the second phase

months, construction is expected to start in August 2021 and construction is expected to be completed in August 2023.

Construction content and composition: The project will be constructed in two phases. The first phase will build a 120,000-ton/year n-propionaldehyde plant, an 80,000-ton/year n-propanol plant and a 40,000-ton/year propionic acid plant. The second phase will be constructed. 12

10,000 tons/year n-propionaldehyde plant, 80,000 tons/year n-propanol plant, 40,000 tons/year propionic acid plant and 8

10,000 tons/year propyl acetate plant, including the construction of ethylene purifier, synthesis gas purifier, formylation reactor, propionaldehyde rectification tower, tail gas absorption tower, tail gas analysis tower, tail gas rectification tower, propionaldehyde hydrogenation reaction equipment, propanol light removal tower, propanol weight removal tower, propionic acid reactor, absorption tower, propionic acid rectification tower, RCO and other equipment, supporting the construction of propionaldehyde finished product tank, propanol finished product tank, propionic acid finished product tank, acetic acid finished product tank Propyl ester finished product tank, acetic acid raw material tank, propionaldehyde intermediate tank, propanol intermediate tank, propionic acid intermediate tank, propyl acetate intermediate tank, catalyst tank, waste liquid tank, refrigeration unit, etc. Other public auxiliary facilities of this project rely on existing projects and facilities in the park.

The main project of this project is shown in the table below.

14.034 billion yuan! Luxi plans to build caprolactam and ethylene downstream integration projects

As early as December 24, 2020, Luxi Chemical announced that the company plans to further extend, supplement and strengthen the chain, and continuously develop high-precision, high-value-added, high-tech, low-energy-consumption products, relying on the integration and intensification of the park. , industrial park, intelligent and engineering advantages, it is planned to invest in the construction of a 600,000-ton/year caprolactam-nylon 6 project, a 1.2 million-ton/year bisphenol A project, and a 240,000-ton/year ethylene downstream integration project, which will be implemented in stages. , continue to improve the industrial layout of the park.

01. 600,000 tons/year caprolactam·nylon 6 project

The 600,000-ton/year caprolactam·nylon 6 project mainly includes: caprolactam, nylon 6 and auxiliary facilities such as supporting production facilities and public works. The total investment is expected to be 6.461 billion yuan, which will be implemented step by step. The monetary funds used in the construction are mainly raised by the company itself, bank loans and other financing methods to ensure the smooth implementation of the project construction. After the project is completed and put into operation, 600,000 tons/year of caprolactam, 600,000 tons/year of nylon 6 and supporting products can be added.

The company’s existing caprolactam and nylon 6 production plants have maintained safe and stable operation since they were put into operation. The unit product consumption and product quality have reached the domestic advanced level. The technology is mature and reliable. To expand the scale of advantageous products, it is planned to continue to invest in the construction of this project.

02, 1.2 million tons/year bisphenol A project

The 1.2 million tons/year bisphenol A project is expected to have a total investment of 6.387 billion yuan and will be implemented step by step. The monetary funds used in the project construction are mainly raised through the company’s own financing, bank loans and other financing methods to ensure the smooth implementation of the project construction. After the project is completed and put into production, it can provide stable raw materials for the company’s existing polycarbonate plant, reduce the amount of outsourcing, reduce the transportation cost and safety risk of outsourcing raw materials, and improve profitability.

03, 240,000 tons/year ethylene downstream integration project

The 240,000-ton/year ethylene downstream integration project, with an estimated total investment of 1.186 billion yuan, will be implemented step by step. The monetary funds used in the project construction are mainly raised by the company itself, bank loans and other financing methods to ensure the smooth implementation of the project construction. This project is a downstream extension project of the company’s existing ethylene products. After the project is completed and put into production, high value-added products such as propanol, propionic acid and propionaldehyde can be added to further enrich the industrial chain of the park.

The current production capacity of Luxi Chemical involves three major fields: new chemical materials, basic chemical products and fertilizer products. Mainly include new chemical materials (200,000 tons of caprolactam, 200,000 tons of nylon 6, 200,000 tons of polycarbonate), basic chemical products (400,000 tons of caustic soda, 750,000 tons of butanol, 220,000 tons of methane chloride, 400,000 tons of tons of formic acid, 100,000 tons of sodium formate, etc.), fertilizer products (900,000 tons of urea, 1.7 million tons of compound fertilizer).