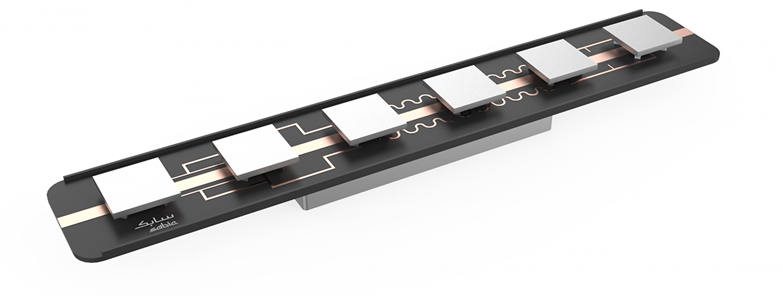

Latest: Globally diversified chemical company Saudi Basic Industries Corporation (SABIC) today introduced its first surface mount technology (SMT) based material based on polyetherimide (PEI) resin – ULTEM™

3473 Resin. This new product is designed to respond to the market trend of miniaturization and weight reduction of 5G base stations by providing metal replacement. For example, ULTEM 3473 resin helps reduce the weight of metal cavity filters by up to

40%. In a typical base station with a massive MIMO antenna filter, this weight reduction can be significant. In addition, the new resin enables innovative designs of antenna filter integration (AFU) that cannot be achieved with metal. With the injection molding process, the cavity of the antenna element and the RF cavity filter can be produced in one piece. This approach simplifies the production process and promises additional weight savings and system cost savings.

“In our close collaboration with industry-leading companies, we have witnessed an increasing number of 5G communications equipment manufacturers use lightweight materials to make it easier and faster to assemble, transport and install these components.” SABIC

Wang Liqiu, senior business manager, said. “We are committed to helping our customers achieve their design goals by providing an effective alternative to metal and helping to achieve an all-in-one antenna filter design.”

Performance, processing and assembly advantages

Compared with metals and some thermoplastics, the new ULTEM

3473 resin has more advantages in product performance, processing and assembly. Parts produced with this new resin for surface mount technology (SMT) can withstand extreme short-term high temperatures of up to 260°C during assembly. Thanks to ULTEM

3473 resin has a metal-like coefficient of thermal expansion (CTE), so

Provides long-term dimensional stability over a wide operating temperature range. The dimensional stability of the material also helps ensure consistent signal filtering in cavity filters by minimizing dimensional changes over these temperature ranges. According to SABIC’s internal tests, the coefficient of thermal expansion of plastic materials with low glass transition temperature increases significantly at temperatures above 85°C to 90°C.

ULTEM

In addition to the two advantages of low thermal expansion coefficient and suitable surface mount technology, 3473 resin can also provide excellent surface metallization performance in metallization process, thus ensuring good adhesion between metal layer and plastic, At the same time reduce the surface roughness. These advantages help reduce signal loss and ensure long-term component reliability.

For customers, ULTEM compares to similar products made from metal

3473 resin helps to significantly shorten the production cycle of new antenna filter units. Applying injection molding to integrate multiple components can help manufacturers increase production capacity and respond more quickly to market demand for 5G

The growing demand for components is expected to further reduce the weight and system cost of 5G base stations.

“Our new ULTEM 3473 resin is the first product in its portfolio designed for 5G base stations and other electronic devices,” said SABIC senior researcher Jiang Siguang.

“In addition to key properties such as good dielectric constant and dissipation factor, this material can also provide excellent thermal performance in SMT assembly processes. The improved flow properties also help customers to miniaturize complex designs. ULTEM

3473 resin is not only an excellent product choice for 5G communication equipment, but also is expected to be used in other fields such as industrial or electrical that have higher requirements for lightweight solutions. ”

SABIC’s new ULTEM 3473 resin is now available for global markets.